|

Liquid Filling Machine Series

|

|

We specialize in manufacturing

pharmaceutical machines

for pharmaceutical , biotechnology and food factory …etc. Our

Liquid Filling Machine can be used for eye

drops , vials , Syrups , Shampoo , Shower gel , Lotions , Liquid

Soap , Oil (Motor and cooking oil) , Dish Washing Liquid ,

Detergent , Sucrose , Honey , Beverages , Pharmaceutical &

Chemical Liquid or similar products. Filling / plugging /

capping process.

Applicable industry:Pharmacy,

Biotechnology, Health Supplements, Nutritional Supplements,

natural food…etc.

Liquid

Filling Sealing Machine Series include

Aseptic Filling, Stoppering

& Closing Machine (Vial / Eye-Drop) ,

Liquid Filing, Plugging, &

Capping Machine,

Volumetric Liquid Filling &

Capping Machine

,

High Viscosity Liquid Filling

Machine,

Volumetric Liquid Filling Machine,

Level Control Liquid Filling

Machine,

Semi- Volumeteric Liquid

Filling Machine,

Semi-Automatic

Level Control Liquid Filling Machine,

Capping Machine

…etc.

|

|

|

|

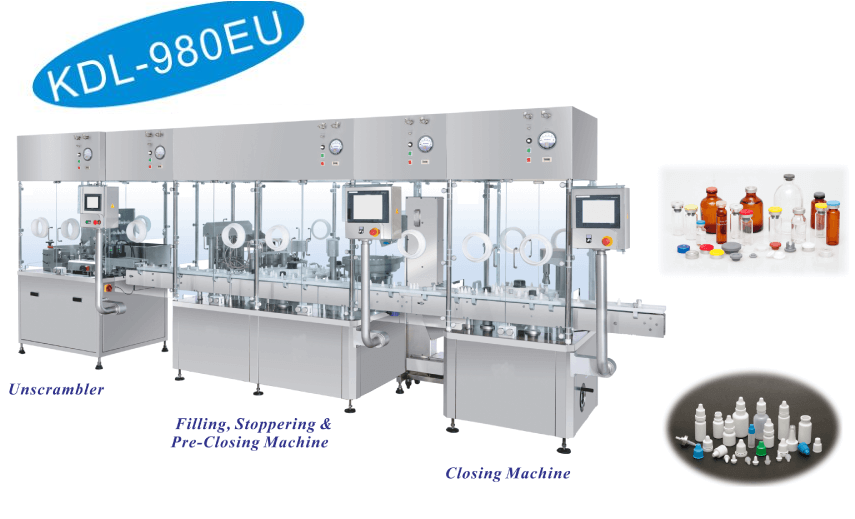

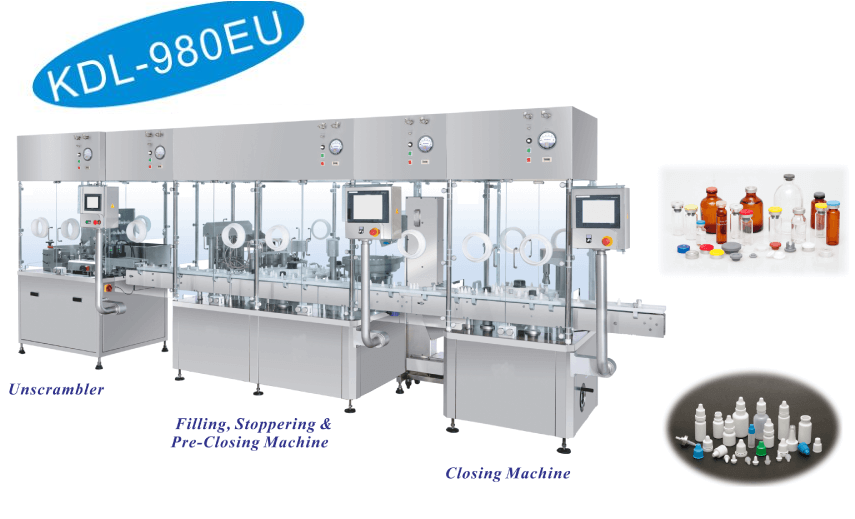

Aseptic

Filling, Stoppering & Closing Machine (Vial /

Eye-Drop) |

|

KDL-980EU |

Kwang Dah

accumulated a lot of producing experience in liquid

filling, stoppering & closing machine for many

years. We developed the In-Line Aseptic Preparation

Machine which is designed for vials & eye-drops.

It can be equipped with unscrambler, nitrogen

filling, liquid filling, stoppering, pre-closing, &

closing machine become a complete In-Line eye drop

processing machine.

It also can equipped with turn table, nitrogen

filling, liquid filling, rubber stoppering &

aluminum cap closing machine become a complete

In-Line vials processing machine.

In accordance

with PIC/S GMP & Aseptic Preparation requirements,

machine using many high precision servo controllers

& combined PLC & HMI for production operation &

adjustment, therefore“ONE TOUCH” will automatically

adjust the conditions of production during

production operation or adjusting, it is a

user-friendly with high-efficiency machines.

Max. Capacity: 100 Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

This KDL-980 series machine is an automatic

liquid filling, plugging, & capping machine.

It is capable of filling small containers

(2cc to 60cc) including eyedrops, vials,

cosmetics, & other types containers.

This monoblock type machine consist of bottle

feeding, nitrogen air filling, liquid filling,

plugging, and capping.

Max. Capacity: 50~100 Bottles/Minute.

|

|

|

|

|

|

|

|

This KDL-980SG machine is an automatic liquid

filling, plugging & capping machine.

It is capable of filling small containers ( 2cc

to 100cc ) including eye-drops, vials,

cosmetics, & other types containers. This

monoblock type machine consist of bottle

feeding, nitrogen air filling, liquid filling,

plugging, and capping.

Suitable for pharmaceutical, cosmetic,

nutrition, Food industries etc.

Max. Capacity: 50~100 Bottles/Minute.

|

|

|

|

|

|

|

|

|

KDL-950

|

|

The KDL-950 is a compact combination set of

liquid filling & capping machine. Accurate

volumetric filling designed by stainless steel

cylindrical piston. This machine can filled

pharmaceutical or chemical liquids, lotions,

oils, cosmetics, beverages, syrups, sauces, etc.

Max. Capacity: 60 Bottles/Minute.

|

|

|

|

|

|

KDL-700

|

|

This KDL-700 is a machine that was specially

developed in order to fill high viscosity liquid

products such as shampoo, shower gel, lotions,

oils (motor oil & cooking oil), etc.

This machine can also fill on low viscosity

liquid products.

Max. Capacity: 60 Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

|

This

KDL-650 is a liquid filling machine that is a

volumetric filling designed by stainless steel

cylindrical piston.

This machine can filled pharmaceutical or

chemical liquids, oils, beverages, etc.

Max. Capacity: 60

Bottles/Minute.

...more |

|

|

|

|

|

|

|

|

|

The KDL-600 is a liquid filling that is a level

control by diaphragm pump not necessary to

adjust machine when filling volume changed.

This machine can fill on pharmaceutical &

chemical liquids, cosmetics, oils, sauces, etc.

Max. Capacity: 60 Bottles/Minute.

...more |

|

|

|

|

|

|

|

|

|

|

The KDL-250 is a two-tube type semi-automatic

volumetric liquid filling machine.

It is applicable on all types of chemicals or

pharmaceuticals liquid products, oils,

beverages, lotions, sauces, etc.

Max. Capacity: 40 Bottles/Minute.

|

|

|

|

|

|

|

|

*Uniform filling level suitable for glass or

hard plastic bottles.

*Suitable for various shape & different

size containers.

*All stainless construction meeting

G.M.P. requirements.

Max. Capacity: 30 Bottles/Minute.

|

|

|

|

|