GENERAL:

Kwang Dah started to manufacture Blister Packing Machinery

KDB-120 since 1991. These extraordinary machinery totally satisfy

customer's need in Pharmaceutical / Food / Nutrition / Health Care

industry…..etc.

In forecasting of world trend of cGMP & PIC/S GMP packing

requirement, after years of research and developing , we endeavor to

modify these machine to match Europe standard requirement, this

significant achievement has settled customer's anxiety while

producing on line. This compact size machine with all

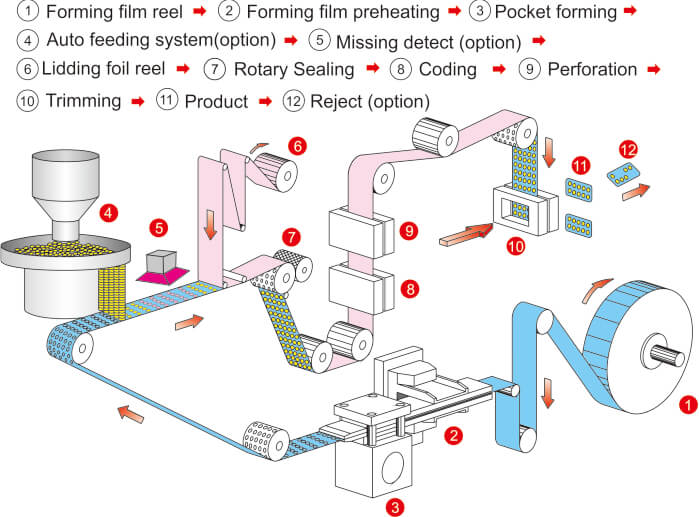

functions, starting from Forming film preheating, Pocket forming,

Auto feeding, Missing detect, Rotary sealing, Coding, Perforation,

Trimming to final product, offering end user automatic production

process, save cost and more efficient (see Flow Chart).

Applicable industry:Pharmacy,

Biotechnology, Health Supplements, Nutritional Supplements, natural

food…etc.

|

FLOW CHART:

FEATURES:

|

1.

|

Compact size with all functions in one, low noise , no

public hazards.

|

|

2.

|

Equipped with detection panel system which displays

where the trouble is. |

|

3.

|

Advantage Capsule Orientation, Auto Feeding, Irregular

Shape Tablets feeding ...etc functions, others

competitors can not compare it. |

|

4.

|

Rotary Sealing System (continue motion) offering best

auto-feeding condition better than plate type

(intermittent system) , resulting in a beautiful

appearance and better seal up ability. |

|

5.

|

By

advantage Rotary Sealing System sealing instantaneously

to prevent high temperature

getting into the blister pockets, not effect medicine

characteristic. |

|

6.

|

Rotary Sealing System provide instantaneously sealing,

resulting in a beautiful appearance and better seal-up

ability. |

|

7.

|

Cross Net Sealing isolate Oxygen and Humidity getting

into blister pocket, will not affect medicine

characteristic, can lasted longer over 4 times shelf

life compare to other plate type machine. |

|

8.

|

Trimming by precise Index, not waste packing material

between two blisters and saves material cost. |

|

9.

|

Mechanical transmission design , moving precisely and

more save power. |

|

10. |

Equipped with 2 precise Index keep production process

more precisely. |

|

11. |

It

is very easy to exchange all the size change parts. It

takes less than 30 minutes, friendly design unskilled

operator can running machine easily. |

|

12. |

Main frame covered with stainless steel, antirust, easy

clean. |

|

13. |

Meet cGPM & PIC/S GMP standard. |

|

14. |

Capable of connect to cartoning machine (See KDM-920) |

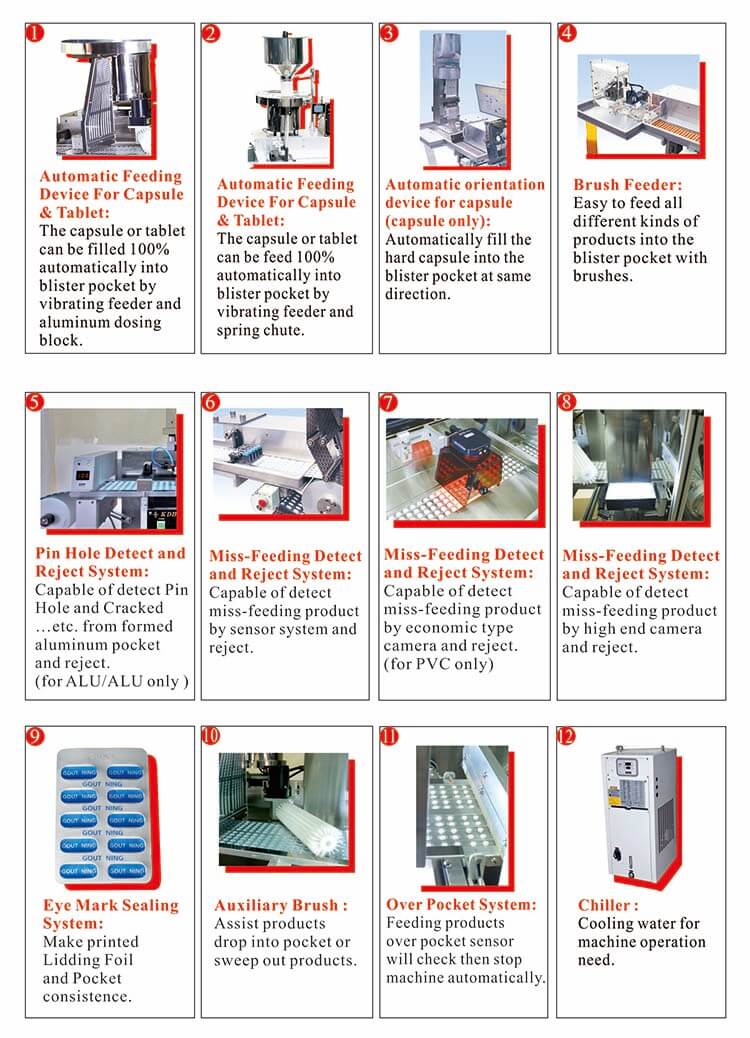

OPTION:

KDB

MACHINE

Sealing Line (cross-net type) |

|

TRADITIONAL MACHINE

Sealing Dot (plate type) |

|

|

|

|

Cross-net type sealing (Rotary type sealing) :

Due to crossed net sealing is capable of blocking

the air completely and prolonging medicine

preservation about 4 times over plate type sealing.

The cross-net sealing is composed of two rollers

compressed in a single line with a instantaneously

contact area preventing high temperature getting

into the blister pockets, will not affect medicine

characteristic.

|

|

Dot type (plate-type)

Plate type uses dot-type

sealing:air gets into the medicine where there

aren't dots and thus

shortens expiration.

Since the sealing area is larger and sealing time

longer, during the sealing process, hot air easily

gets into the blister pockets. This decreases the

effectiveness of the medicine. |

|

|

|

|

|

|

The machine adopts a no waste cut method, so no

wasted material is

produced. It can save about

1/5 of material compared to traditional types. |

|

Plate-type of triming wastes about 3-5 mm of

material between two blister and increases cost at

the same time. |

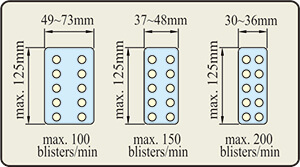

OUTPUT FOR KDB-120:

*Special size available.

|

TECHNICAL DATA

| Model |

KDB-120

|

KDB-120ALU |

| Output |

Max. 200 blisters/min |

Max. 100 blisters/min |

| Forming/Material Width |

Max.140

mm |

| Forming

Depth |

Max.12mm |

Max.9mm |

| Formed

Area Available |

Max.146 x

125mm |

| Reel

Diameter |

Forming

Material |

Max. Φ

400mm |

| Lidding

Material |

Max. Φ

240mm |

| Reel Core |

Φ 70 ~ Φ 76mm |

| Power

Supply |

220V/380V

50HZ/60HZ 1 phase |

| Power

Consumption |

7.2 KW |

8 KW |

| Air

Consumption |

6 kgf/cm²

, 75 ∫/min |

| Forming

Materials |

PVC,

PVC/PVDC

PVC/ACLAR, PP |

Aluminium

laminate,PVC,PP,

PVC/PVDC,PVC/ACLAR,

|

| Lidding

Foil |

ALU/HARD,ALU/SOFT,ALU/PAPER,

ALU/POLYESTER,PP |

| Machine Size (LxWxH) |

260x95x200 (cm) |

| Packing

size (LxWxH) |

285x115x175 (cm) |

| Gross

Weight |

1400kgs |

| Net

Weight |

1000kgs |

◎ The specification, appearance and

dimensions shall be subject to change without

prior notice.

◎ Other KD machine series please browse our

website check to detail. |

|

|