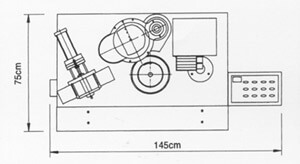

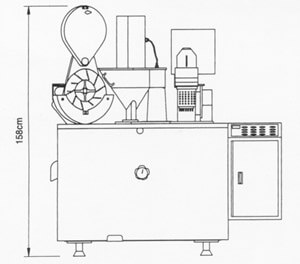

KDF-2 Vertical Semi-Automatic Capsule Filling Machine (Discontinued)

GENERAL:

Since 1971 KWANG DAH has

specialized in the manufacturer of capsule series machines such as :

auto capsule filling machine, blister packing machine batch counter,

polishing machine, inspection machine and strip packing machine.

KDF-2 is a new semi-automatic capsule filling machinewhich is a

improved machine from type 8 filling machine.

This improvement results in faster production, meeting G.M.P.

requirment, more accurate filling, safer operation, simple

maintenance, no noise, easy clean and less labor.

FEATURES:

|

|

All stainless shells, hoppers, machine table.ets. meet G.M.P.

requirement. |

|

|

Infinitely variable speed of filling tablet with independent

power and fix point filling that result in accurate dosage. |

|

|

No painting finish on the machine surface thus it can avoid that

the paint strip off and mix into the powder, then fill into the

capsules.. |

|

|

A hydraulic join system can increase join power and smoothen

join without any damage of capsule. |

|

|

A special design allows for changing mold for different size

capsules within 15 minutes easily, simply, precisely. |

|

6.

|

Simple structure and low malfunction, easy to maintain and

clean. |

|

7.

|

Simple operation, only one operator required, and operating

training can be done in 10 minutes. |

|

8.

|

No noise, no public harm. |

|

|

|

|

|

|

|

|

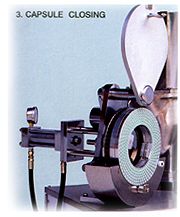

OPERATIONS:

There are 3 stations in this semi-auto capsule filling machine(KDF-2).

The first one is orientation of capsule, the second one

is powder filling ,and the last one is capsule closing.

|

|

THE FIRST STATION:ORIENTATION OF

CAPSULE

The functions of first station include capsule feeding, aligning

and insertion into bores of holding ring . Also, vacuum is used

for separating capsule cap and body in first station. After

orientation of capsule, capsule cap can stay in upper holding

ring and capsule body can stay in lower holding ring. |

|