KDS-800 Strip Packaging Machine

|

|

GENERAL:

The KDS-800 is

designed to package solid products in strips pocket for

higher level preservation requirement.

By higher level Aluminum laminate material , double side

aluminum film sealing technology successfully isolate oxygen

and humidity, compare with blister pack machine KDS-800

obviously over blister pack machine present high quality

level.

This machine can be used in any heat seal material.

Products are sealed within pockets formed by two moving

film, through two sealing roller makes seal around the thick

layer strip pockets thus products shelf life can be lasted

longer.

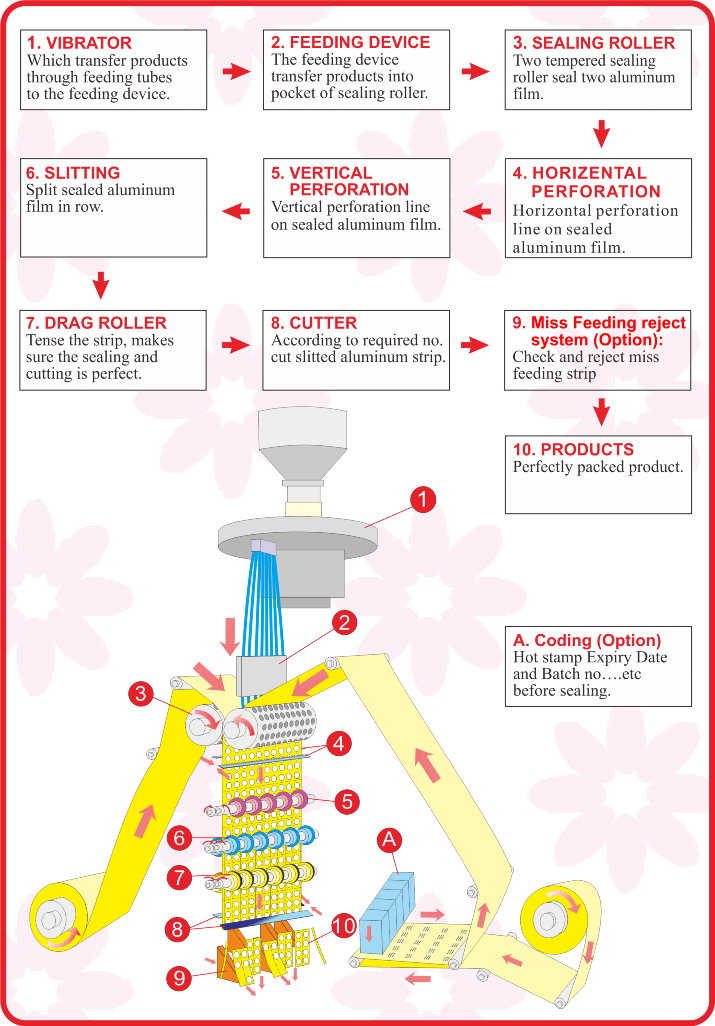

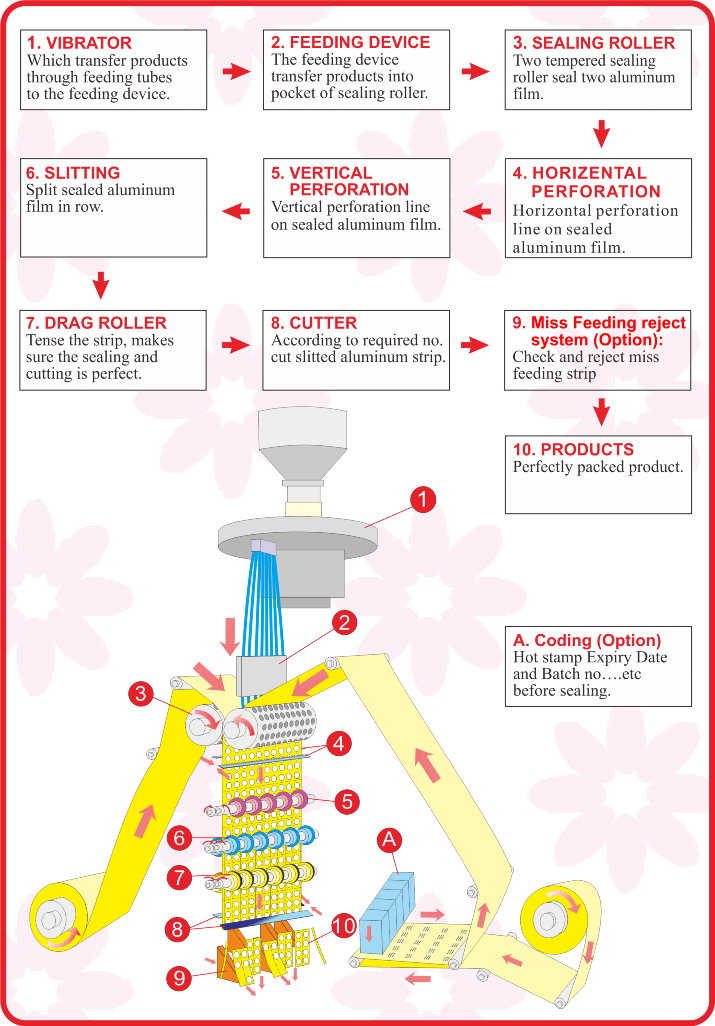

It equipped with Vibrator, Feeding Device, Rotary Sealing

Roller

Horizontal Perforation, Vertical Perforation, Slitting, Drag

Roller,

Miss Feeding Reject System , Cutter to final product (see

Flow Chart).

It is suitable for Pharmaceutical / Food / Nutrition /

Health Care / Chemical industry ….etc.

Applicable industry:Pharmacy,

Biotechnology, Health Supplements, Nutritional Supplements,

natural food…etc.

|

|

FEATURES: |

|

1. |

Compact size with all

function and fast production. |

|

2. |

Used two roller

sealing make around the pockets form a hermetic seal thus

offering maximum shelf life to the product contained within

strip pocket. |

|

3. |

Higher level Aluminum

laminate material , more thick double side aluminum film

sealing technology successfully isolate oxygen and humidity. |

|

4. |

It is very easy to

exchange all the size change parts. It takes less than 30

minutes to finish. |

|

5. |

Main frame is covered

with stainless steel. Easy clean. |

|

6. |

Apply to cGPM & PIC/S

GMP standard. |

|

7. |

Automatic feeding,

Sealing, Perforation ,Slitting and Cutting are done

simultaneously.

Therefore, its efficiency is high, meaning production cost

is decreased due to reduction of labor cost. |

|

8. |

Compact and

constructed simply, the machine can be maintained easily,

operates with low noise. |

|

9. |

When packing operation

is completed, the product shall be absolutely sealed and

beautifully looked at. This certainly improve the quality of

the product. |

|

10. |

User friendly design

operators are getting operation on hand easily. |

|

11. |

With precise PID

temperature control system successfully control roller in

required working temperature. |

|

12. |

Adjustable cutting

selection set up row cutting line (1~99). |

|

13. |

Unique slitting and

cutting device make a beautiful appearance on strip cutting

edge. |

|

14. |

Hot Stamping Device

help stamp batch no. or expiry date. (Option) |

|

15. |

Perforation Device

(Horizontal) tear strip easily. (Option) |

16.

|

Miss Feed reject

system , make sure products are feed into strip pocket other

wise will reject automatically. (Option) |

|

|

FLOW CHART :

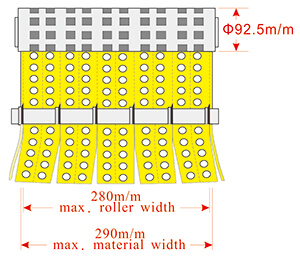

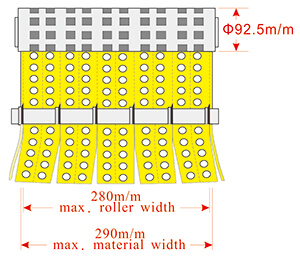

SPECIFICATION:

SPECIFICATION:

TECHNICAL DATA:

|

Capacity

|

Max. 70,000 pcs/hr ( Φ5 m/m TABLET ) |

| Pack

Material |

ALUMINUM,

COATED PAPER,

COMPOUND

FOIL, CELLOPHANE |

| Line |

1~10

|

|

Power Consumption |

2.5KW |

|

AIR Consumption |

6 kgf/

cm² , 200 ∫/min |

|

Power Supply |

AC220V

50/60 Hz 1phase |

|

Machine Size (LxWxH) |

90 x 140

x 225 (cm) |

|

Packing size (LxWxH) |

110 x 160

x 175 (cm) |

|

Gross Weight |

600 kg |

|

Net Weight |

700 kg |

|

|

|