|

| Home>Main Products>Capsule Filling Machine Series |

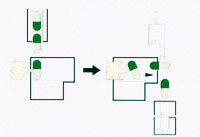

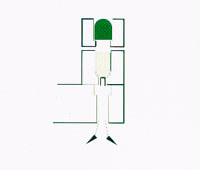

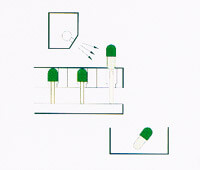

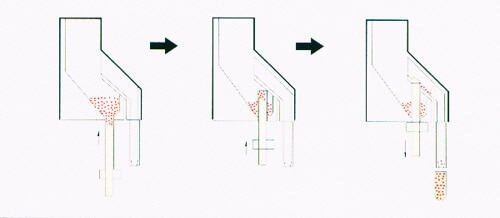

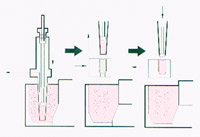

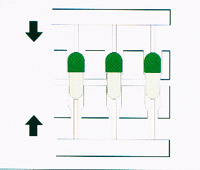

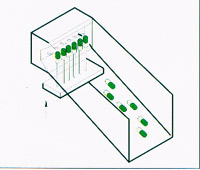

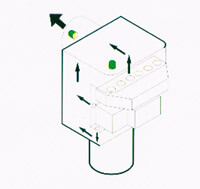

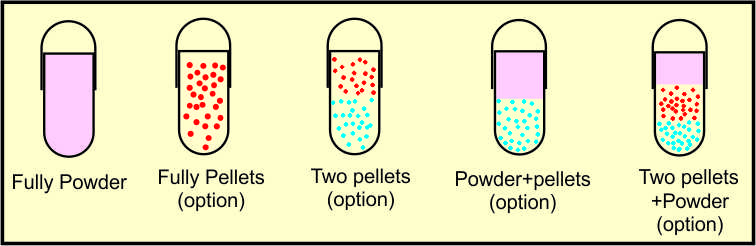

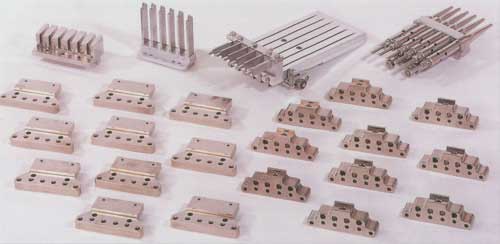

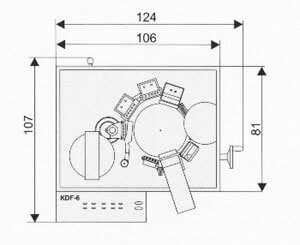

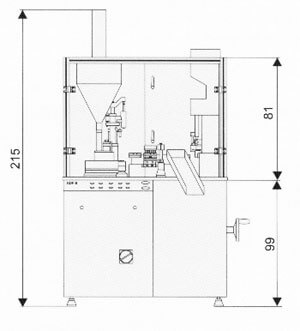

KDF-6 Automatic Capsule Filling Machine

|

|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

◎

The specification, appearance and dimensions shall

be subject to change without prior notice.

|

|||||||||||||||||||||||||||

|

KDF-6 Capsule Granule/Powde Filling Sealing Machine

|

|

[ Company Profile ]

|

[

Product Profile ]

|

[

Contact Us ]

|

[

Home ]

|

http://www.kd-machine.com (Try this webside)

If you don't know which machine you need ↑↑

E-mail: kd033512@gmail.com We'll reply your enquiry within 24hrs.

TEL:886-2-29713333,886-2-29818888 FAX:886-2-2982-6645

No.17. Lane 32, Gengzhou Rd., Wugu Dist., New Taipei City, 24874. Taiwan.